Based on the rich experience accumulated over the years, our company has summed up the perfect design theory, which can ingeniously conceive various kinds of reaction indoor and outdoor mechanisms according to different projects, different reaction mechanism and condition requirements, and design a variety of electrolytic reaction devices that can meet various medium, flow rate, reaction time, temperature and other harsh process conditions; so far, our company has been successful We have completed the design and manufacture of various inorganic and organic electrosynthesis devices, including potassium chlorate, potassium perchlorate, potassium hydroxide, sodium hydroxide, ferrous sulfate, glyoxylic acid, sebacic acid, acetonitrile, vanillin, cysteine, calcium gluconate, succinic acid, p-aminophenol, desalination of seawater, ultrafine powder, etc. We sincerely hope to make use of our professional knowledge, Develop more electrosynthetic products and make greater contribution to improve the technology level of electrolysis industry!

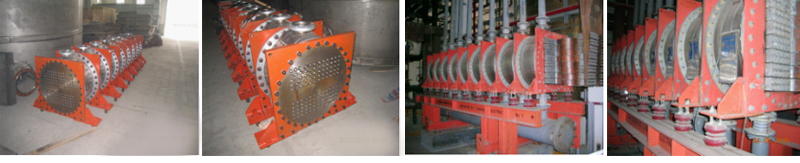

Monopolar chlorate electrolyzer

|

Model |

Model: FG-II20 |

FG-II25 |

FG-II30 |

FG-II60 |

FG-II80 |

|

Electrolysis area |

10M2 |

12.5M2 |

15M2 |

30M2 |

40M2 |

|

Anode material |

MMO/TA1 |

MMO/TA1 |

MMO/TA1 |

MMO/TA1 |

MMO/TA1 |

|

Cathode material |

Active cathode, carbon steel |

Active cathode, carbon steel |

Active cathode, carbon steel |

Active cathode, carbon steel |

Active cathode, carbon steel |

|

Design current density |

2200-3000A/M2 |

2000-3000A/M2 |

2000-3000A/M2 |

2000-3000A/M2 |

2000-3000A/M2 |

|

Electrode distance |

2.5mm~3mm |

2.5mm~3mm |

2.5mm~3mm |

2.5mm~3mm |

2.5mm~3mm |

|

Anode coating |

Five element nano coating |

Five element nano coating |

Five element nano coating |

Five element nano coating |

Five element nano coating |

|

Anode life |

>6year |

>6year |

>6year |

>6year |

>6year |

|

oxygen content |

<3% |

<3% |

<3% |

<3% |

<3% |

|

current efficiency |

>93% |

>93% |

>93% |

>93% |

>93% |

|

Shell material |

Carbon steel and titanium |

Carbon steel and titanium |

Carbon steel and titanium |

Carbon steel and titanium |

Carbon steel and titanium |

|

Chlorate production |

90ton/year |

110ton/year |

130ton/year |

280ton/year |

360ton/year |

|

DC power consumption |

<5000kw/ton |

<5000kw/ton |

<5000kw/ton |

<5000kw/ton |

<5000kw/ton |

|

working temperature |

80℃~85℃ |

80℃~85℃ |

80℃~85℃ |

80℃~85℃ |

80℃~85℃ |

Bipolar chlorate electrolyzer

|

Model |

FG-II40 |

FG-II60 |

FG-II80 |

FG-II120 |

FG-II160 |

|

Electrolysis area |

40M2 |

60M2 |

80M2 |

120M2 |

160M2 |

|

Anode material |

MMO/TA1 |

MMO/TA1 |

MMO/TA1 |

MMO/TA1 |

MMO/TA1 |

|

Cathode material |

Anti bubbling cathode |

Anti bubbling cathode |

Anti bubbling cathode |

Anti bubbling cathode |

Anti bubbling cathode |

|

Design current density |

2200-3000A/M2 |

2000-3000A/M2 |

2000-3000A/M2 |

2000-3000A/M2 |

2000-3000A/M2 |

|

Electrode distance |

2.5mm~3mm |

2.5mm~3mm |

2.5mm~3mm |

2.5mm~3mm |

2.5mm~3mm |

|

Anode coating |

Five element nano coating |

Five element nano coating |

Five element nano coating |

Five element nano coating |

Five element nano coating |

|

Anode life |

>6year |

>6year |

>6year |

>6year |

>6year |

|

oxygen content |

<3% |

<3% |

<3% |

<3% |

<3% |

|

current efficiency |

>93% |

>93% |

>93% |

>93% |

>93% |

|

Shell material |

Carbon steel and titanium |

Carbon steel and titanium |

Carbon steel and titanium |

Carbon steel and titanium |

Carbon steel and titanium |

|

Conductive plate |

Three layer composite conductive material |

Three layer composite conductive material |

Three layer composite conductive material |

Three layer composite conductive material |

Three layer composite conductive material |

|

Chlorate production |

400ton/year |

600ton/year |

800ton/year |

1200ton/year |

1600ton/year |

|

DC power consumption |

<4900kw/ton |

<4900kw/ton |

<4900kw/ton |

<4900kw/ton |

<4900kw/ton |

Energy saving chlorate electrolyzer with high current density

|

Model |

FG-II15 |

FG-II25 |

FG-II30 |

|

Electrolysis area |

15M2 |

25M2 |

30M2 |

|

Anode material |

MMO/TA1 |

MMO/TA1 |

MMO/TA1 |

|

Cathode material |

Anti bubbling cathode |

Anti bubbling cathode |

Anti bubbling cathode |

|

Design current density |

2500-3000A/M2 |

2500-3000A/M2 |

2500-3000A/M2 |

|

Electrode distance |

2.5mm~3mm |

2.5mm~3mm |

2.5mm~3mm |

|

Anode coating |

Six element nano coating |

Six element nano coating |

Six element nano coating |

|

Anode life |

>8year |

>8year |

>8year |

|

oxygen content |

<3% |

<3% |

<3% |

|

current efficiency |

>94% |

>94% |

>94% |

|

Shell material |

titanium |

titanium |

titanium |

|

Conductive plate |

Energy saving compositeConductive plate |

Energy saving compositeConductive plate |

Energy saving compositeConductive plate |

|

Chlorate production |

170ton/year |

300ton/year |

300ton/year |

|

DC power consumption |

<4850kw/ton |

<4850kw/ton |

<4850kw/ton |

Organic synthesis cell type cell

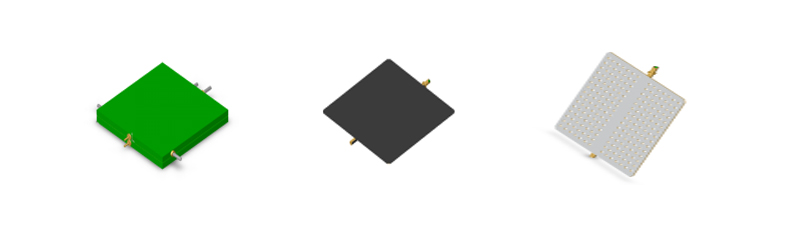

FG series bipolar electrolyzer is a new type of electro-mechanical synthesis device jointly developed by our company and scientific research institute, which is suitable for electro synthesis of organic fine chemical products. Referring to the latest design of foreign related devices, the device takes special engineering plastics or composite metal titanium as the tank body and precious metal deposition active layer as the anode and cathode. It has the advantages of high operating current density, high current efficiency, low tank voltage, excellent corrosion resistance, compact structure, convenient maintenance and no environmental pollution. It is incomparable with other electric synthesis devices, Its excellent performance is bound to give users satisfactory returns

The electrolyzer is composed of several cells. Each cell is divided into cathode area and anode area. The two parts are separated by diaphragm. The positive and negative electrolytes enter into the positive and negative pools for forced circulation through the circulation tank by circulation pump. The cells are connected by wires or copper bars. The cathode pool and the anode pool conduct electricity through electrolyte and film. The current is connected in series. Oxidation products with positive oxidation reaction and reduction products with negative reduction reaction

Model: FG-II20

Electrolysis area: 20M2

Outline size: 800×500×50

Anode material: Precious metal oxide coating

Cathode material: Copper, nickel, leadtitanium

current efficiency: >80%

current density: <500A/M2

Electrode pitch: 2-5MM

working temperature: 50-80℃

Shell material: Carbon steel, stainless steel, polypropylene, lining F4, engineering plastics

Model: FG-II10

Electrolysis area: 10 M2

Outline size: 300×300×50

Anode material: Precious metal oxide coating

Cathode material: Copper, nickel, leadtitanium

current efficiency: >80%

current density: <500A/M2

Electrode pitch: 2-5MM

working temperature: 50-80℃

Shell material: Carbon steel, stainless steel, polypropylene, lining F4, engineering plastics