Application field and principle introduction

Electronic plating technology is one of the indispensable key technologies in modern microelectronics manufacturing. From Damascus copper interconnection electroplating technology on chip, bump electroplating technology in packaging, electroplating surface treatment of lead frame to various functional electroplating of printed circuit board and connector, electronic plating has penetrated into the whole microelectronics industry, and is still developing in the manufacturing of micro devices such as MEMS and micro sensors. In addition, electronic plating is facing the electronic field with high technology content. Compared with conventional decorative and protective plating, it has different types, functions, accuracy, quality and plating methods, with very high technical requirements. In a sense, electronic plating has become a special technology independent of conventional plating. The application field of electronic plating is also different from that of conventional plating. Electronic plating includes PCB plating, lead frame plating, connector plating, microwave device plating and other electronic components plating. The key of PCB electroplating is how to ensure the uniformity of thickness of copper layer on both sides of the substrate and the inner wall of the through hole. In order to obtain the uniformity of coating thickness, it is necessary to ensure that the flow velocity of plating solution in both sides of PCB and through holes is fast and consistent, so as to obtain a thin and uniform diffusion layer. In order to meet the electroplating requirements and adjust to the most appropriate working conditions, the independence described above also allows different current density to be applied. In this way, the result is a higher production speed, for example. Because of the dimensional stability and durability of the insoluble titanium anode, the distance between the anode and the cathode can be kept stable within the service life of the anode, and the anode does not need to be replaced, so it can ensure more consistent product quality in the electroplating process。

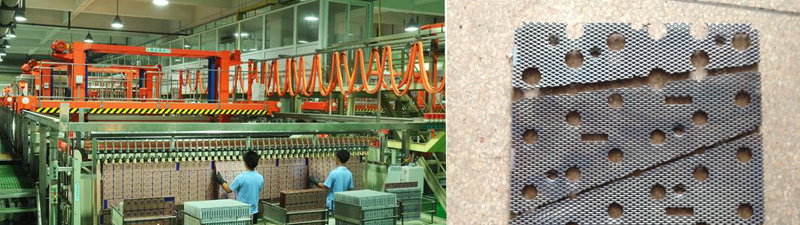

Typical application conditions and product recommendation

Through long-term research and development, our company has accumulated practical experience in producing high-quality anode products required for PCB circuit boards under harsh working conditions. Our company works closely with our customers to design and manufacture anode products suitable for various PCB electroplating processes, including: reverse pulse copper plating process in PCB manufacturing, DC copper plating in PCB manufacturing, gold plating process in PCB manufacturing, semiconductor component electroplating and precious metal electronic plating… …

Vertical continuous DC copper plating of circuit board

Electrolyte : CuSO4•5H2O, 200-240 g/l

H2SO4, 80-100 g/l

Cl-, 40-55 ppm

Additives

Temperature : 20- 70 °C

current density: 100 - 500 A / m² DC

Anode type: titanium anode coated with modified iridium tantalum metal oxide mixture can ensure low consumption of additives.

Circuit board reverse pulse copper plating

Electrolyte: CuSO4•5H2O, 100-300 g/l

H2SO4, 50-150 g/l

Additive

temperature : 20- 70 °C

Current density: generally 500-1000a / m2 forward pulse current and three times reverse pulse current; generally 19ms forward pulse and 1ms reverse pulse; or adjust the current density and pulse time according to the process

Anode type: modified iridium tantalum metal oxide mixture coated titanium anode

Circuit board gold plating

Electrolytes: acid / cyanide systems, brighteners and additives

Au : 4-10 g/l

CN- :Low concentration PH : 4-5

temperature: 50-60 °C

current density: 0.1 – 1.0 ASD;平均 0.2 ASD

Anode type: platinum and IR MMO coating can be used;

The thickness of platinum on electroplated platinum anode can be selected from 1um to 10um, or even thicker

Other fields

Electrolyte :Acid / cyanide systems, brighteners and additives

Au : 4-10 g/l

CN- : Low concentration

PH : 4-5

temperature: 50-60 °C

current density: 0.1 – 1.0 ASD; 平均 0.2 ASD

Anode type: Platinum Plated anode or iridium oxide coating can be used