| Application | Product Center | About us | News | Contact |

|

Chlor alkali chemical industry Electrolytic copper foil Electronic plating Hydrometallurgy Steel plate electroplating Metal plating more + |

Ruthenium Series MMO Anode Iridium Series MMO Anode Platinum Plated Titanium Anode Lead Dioxide Coated Titanium Anode Platinum Plated Niobium Anode BDD Anode Electrolyzer design and production Organic synthesis cell |

Profile Factory |

Company News Industry information |

Sales:(+86)527-8768 6007 (+86)138 1570 1819 Fax:(+86)527-8768 6000 E-mail:szphm@vip.126.com Mr Pan:(+86)136 0621 8252 Mr Chen: (+86)13815701819 Add:No.1, Zhangqi Road, National Economic Development Zone, Shuyang County, Jiangsu Province |

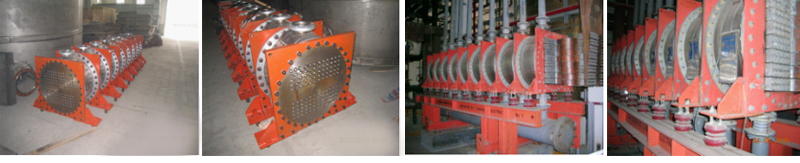

Design and production of electrolytic cell

Based on the rich experience accumulated for many years, our company has concluded a sound design theory.It can cleverly design a variety of different reaction indoor and outdoor mechanisms according to different projects, different reaction mechanisms and conditions, and design to meet various media, A variety of electrolytic reaction devices with severe process conditions such as flow rate, reaction time, temperature, etc .; So far, our company has successfully completed Design and manufacture of electrosynthesis devices for various inorganic and organic substances such as diacid, ethanedinitrile, vanillin, cysteine, calcium gluconate, succinic acid, p-aminophenol, seawater desalination, ultrafine powder, etc. We sincerely hope to use our company's expertise to develop more electrosynthetic products and make greater contributions to improving the technological level of the electrolytic industry!

Monopolar chlorate electrolytic cell

|

Model |

FG-II20 |

FG-II25 |

FG-II30 |

FG-II60 |

FG-II80 |

|

Electrolysis area |

10M2 |

12.5M2 |

15M2 |

30M2 |

40M2 |

|

Anode material |

MMO/TA1 |

MMO/TA1 |

MMO/TA1 |

MMO/TA1 |

MMO/TA1 |

|

Cathode material |

Active cathode, carbon steel |

Active cathode, carbon steel |

Active cathode, carbon steel |

Active cathode, carbon steel |

Active cathode, carbon steel |

|

Design current density |

2200-3000A/M2 |

2000-3000A/M2 |

2000-3000A/M2 |

2000-3000A/M2 |

2000-3000A/M2 |

|

Electrode distance |

2.5mm~3mm |

2.5mm~3mm |

2.5mm~3mm |

2.5mm~3mm |

2.5mm~3mm |

|

Anode coating |

Five yuan nano coating |

Five yuan nano coating |

Five yuan nano coating |

Five yuan nano coating |

Five yuan nano coating |

|

Anode life |

>6year |

>6year |

>6year |

>6year |

>6year |

|

Oxygen content |

<3% |

<3% |

<3% |

<3% |

<3% |

|

Current efficiency |

>93% |

>93% |

>93% |

>93% |

>93% |

|

Housing material |

Carbon steel, titanium |

Carbon steel, titanium |

Carbon steel, titanium |

Carbon steel, titanium |

Carbon steel, titanium |

|

Chlorate production |

90T / year |

110T / year |

130T / year |

280T / year |

360T / year |

|

DC power consumption |

<5000kw/T |

<5000kw/T |

<5000kw/T |

<5000kw/T |

<5000kw/T |

|

Operating temperature |

80℃~85℃ |

80℃~85℃ |

80℃~85℃ |

80℃~85℃ |

80℃~85℃ |

Bipolar chlorate electrolytic cell

|

model |

FG-II40 |

FG-II60 |

FG-II80 |

FG-II120 |

FG-II160 |

|

Electrolysis area |

40M2 |

60M2 |

80M2 |

120M2 |

160M2 |

|

Anode material |

MMO/TA1 |

MMO/TA1 |

MMO/TA1 |

MMO/TA1 |

MMO/TA1 |

|

Cathode material |

Anti-bubble cathode |

Anti-bubble cathode |

Anti-bubble cathode |

Anti-bubble cathode |

Anti-bubble cathode |

|

Design current density |

2200-3000A/M2 |

2000-3000A/M2 |

2000-3000A/M2 |

2000-3000A/M2 |

2000-3000A/M2 |

|

Electrode distance |

2.5mm~3mm |

2.5mm~3mm |

2.5mm~3mm |

2.5mm~3mm |

2.5mm~3mm |

|

Anode coating |

Five yuan nano coating |

Five yuan nano coating |

Five yuan nano coating |

Five yuan nano coating |

Five yuan nano coating |

|

Anode life |

>6year |

>6year |

>6year |

>6year |

>6year |

|

Oxygen content |

<3% |

<3% |

<3% |

<3% |

<3% |

|

Current efficiency |

>93% |

>93% |

>93% |

>93% |

>93% |

|

Housing material |

Carbon steel, titanium |

Carbon steel, titanium |

Carbon steel, titanium |

Carbon steel, titanium |

Carbon steel, titanium |

|

Conductive plate |

Three-layer composite conductive material |

Three-layer composite conductive material |

Three-layer composite conductive material |

Three-layer composite conductive material |

Three-layer composite conductive material |

|

Chlorate production |

400T / year |

600T / year |

800T / year |

1200T / year |

1600T / year |

|

DC power consumption |

<4900kw/T |

<4900kw/T |

<4900kw/T |

<4900kw/T |

<4900kw/T |

High current density energy-saving chlorate electrolytic cell

|

Model |

FG-II15 |

FG-II25 |

FG-II30 |

|

Electrolysis area |

15M2 |

25M2 |

30M2 |

|

Anode material |

MMO/TA1 |

MMO/TA1 |

MMO/TA1 |

|

Cathode material |

Anti-bubble cathode |

Anti-bubble cathode |

Anti-bubble cathode |

|

Design current density |

2500-3000A/M2 |

2500-3000A/M2 |

2500-3000A/M2 |

|

Electrode distance |

2.5mm~3mm |

2.5mm~3mm |

2.5mm~3mm |

|

Anode coating |

Hexavalent nano coating |

Hexavalent nano coating |

Hexavalent nano coating |

|

Anode life |

>8year |

>8year |

>8year |

|

Oxygen content |

<3% |

<3% |

<3% |

|

Current efficiency |

>94% |

>94% |

>94% |

|

Housing material |

titanium |

titanium |

titanium |

|

Conductive plate |

Energy-saving composite conductive plate |

Energy-saving composite conductive plate |

Energy-saving composite conductive plate |

|

Chlorate production |

170T / year |

300T / year |

300T / year |

|

DC power consumption |

<4850kw/T |

<4850kw/T |

<4850kw/T |

Organic synthesis electrolytic cell type electrolytic cell